Punctual Delivery Time

With Stocking PossibilityRealization and Assembly

In a Single Operative UnitHigh Standard Labors

Using Scheduled QCOur Services

At Simec, we’re dedicated to making the finest parts and products for our customers. As a part of our machine shop’s services, whether for custom machining, surface treatment, assembly or other applications, the team at Simec provides a positive and proactive customer experience. By collaborating alongside you, we learn about your needs and requirements, providing us with the means to develop a viable solution that’s completed from start to finish at our facility in Treviglio, Italy.

Our one-of-a-kind combination of technical experience, advanced equipment capabilities and customer-centric approach distinguish us from other machine shops with precision CNC capabilities.

Within the company there is a warehouse containing the raw materials needed to a quick answer to urgent requests of the customers. Due to the external partners, our machine workshop is able to provide a complete service of heating treatments, galvanic treatments, covering treatments and painting.

Simec, internally also has a department equipped for the assembly of mechanical products in order to ensure the highest quality to the customer.

The Simec Facility

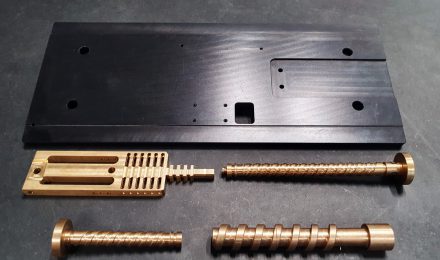

CNC Milling

CNC milling service is dedicated to creating complex geometries and features on plastic and metal parts for medium/low-volume manufacturing. We have two three-axis CNC machining centers and one five-axis CNC machine. Our CNC milling services are designed to provide you with a complete and rapid turn-key solution for your next project.

CNC Turning

Turning involves holding the work piece in a horizontally-mounted, adjustable spindle. As the work piece rotates, various cutting tools are applied to the piece to create circular shapes and features like rings, grooves, slots, contours, radii, internal bores and threads. Our lathes can be equipped with an automatic bar feeder and an optional 3th axis.

Assembling

We offer a complete and professional service for the delivery of the finished products to the customer: we manage both the purchase of commercial elements as well as the phase of the final assembly (mechanical, electronical and testing) with the possibility of provide finishing treatments (heat treatment, galvanizing treatments and painting).

Rapid Prototyping

Rapid prototyping consists of specialized manufacturing techniques for making high-quality physical models. Prototypes are meant to be quick and economical, without the need for the investment in hard tooling. Many of our clients need to produce a physical part quickly in order to validate a design or to capture a fleeting sales opportunity.